Micro hole ceramic nozzle

The ceramic nozzle has the characteristics of sucking and spraying, and it can also be called a capillary tube because of its small holes.

Sucking nozzle is mainly used for the handling and positioning of components. During the "pick and place" process, the nozzle can effectively pick up and place electronic components.

Spraying nozzles are commonly used in jetting nozzles and dispensing nozzles to dispense adhesives or other materials on moving substrates at high speeds, ensuring accuracy and consistency for each component.

Jetting nozzles are used in a wide range of applications, such as cleaning equipment, spraying processes, cooling systems and chemical treatments. Their design and use can be divided into the following categories:

Round nozzle: usually used in situations where concentrated spraying is required.

Flat Nozzle: Suitable for applications requiring diffuse spray.

Adjustable nozzle: Provides flexibility to adjust spray angle and flow rate according to needs.

Dispensing nozzles are mainly used to accurately distribute liquid or paste substances to specific locations. These nozzles are widely used in electronics, medical, food packaging and other industries to improve production efficiency and product quality. Their design and use can be divided into the following categories:

Round nozzles: suitable for even distribution of liquids, often used in paint and glue applications.

Flat nozzle: Used when wide dispensing is required, such as sauce dispensing in food packaging.

Micro-volume nozzle: Designed for precise control of small doses of liquid, commonly used in glue applications for electronic components.

About ceramic materials

Alumina and zirconia are the two main materials used in the manufacture of ceramic nozzles, each with different mechanical strength and injection molding properties.

The bending strength of alumina is 350 MPa

Parts with complex shapes can be produced through ceramic injection molding (CIM) technology, and high precision can be maintained during the molding process.(More)

The bending strength of zirconia is 1000 MPa

In terms of mechanical strength, it is more superior, and ceramic injection molding (CIM) is the best. Zirconia generally has higher flexural strength and toughness than alumina, which makes it more advantageous in situations where it can withstand impacts and high loads.(More)

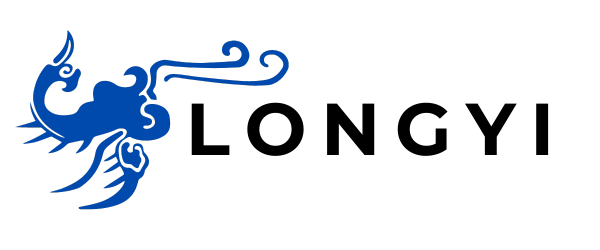

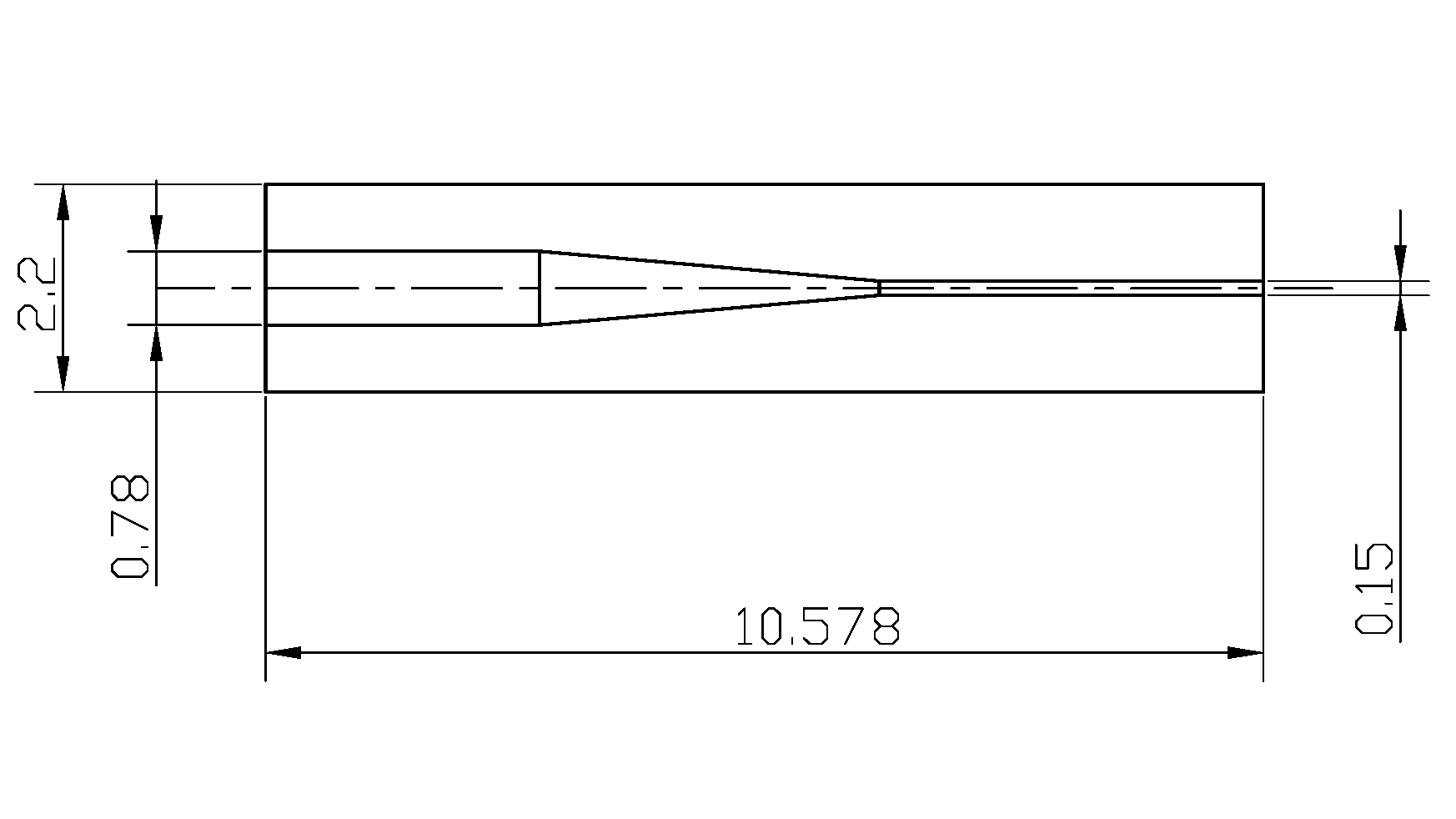

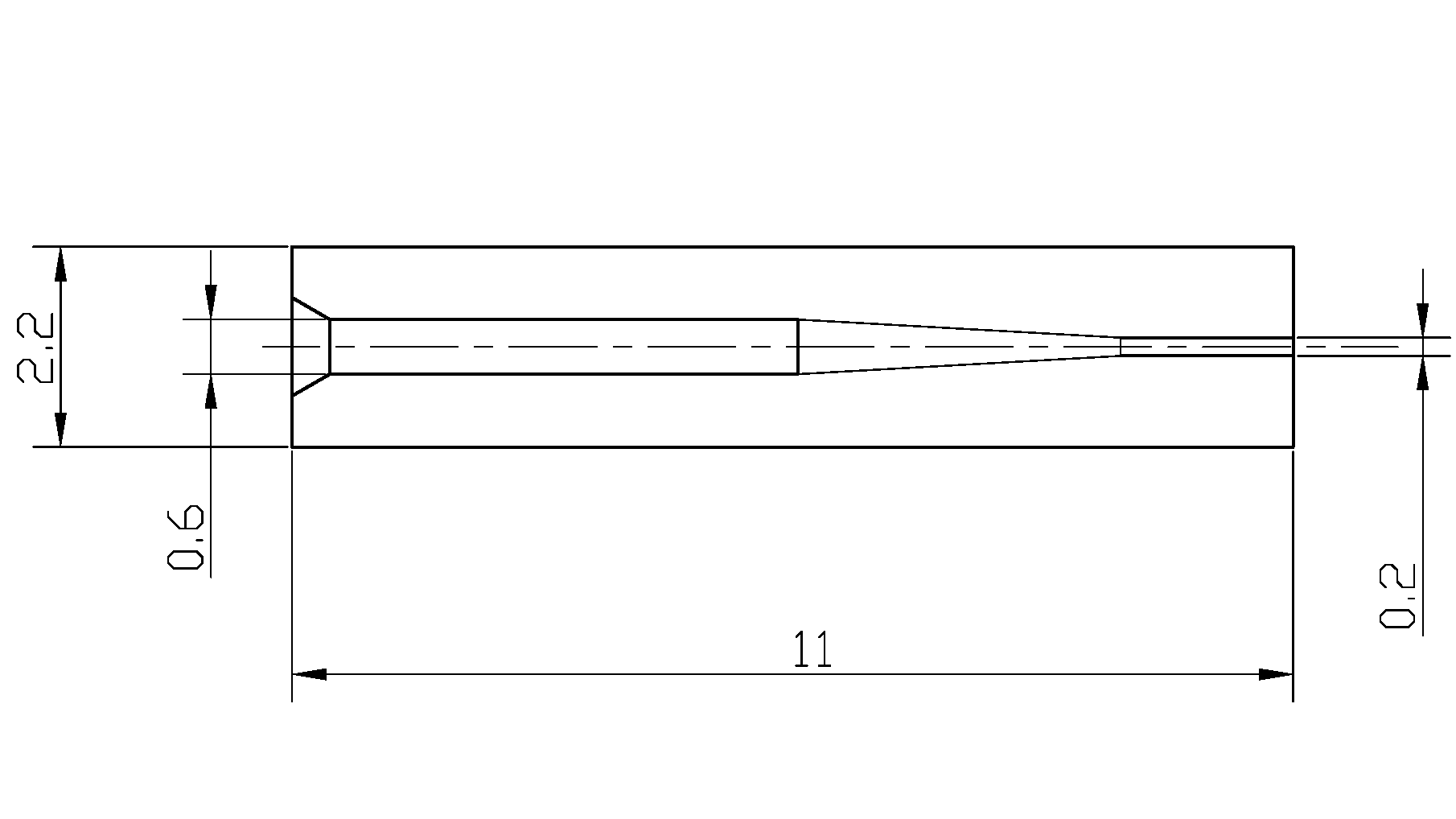

About specification and tolerance

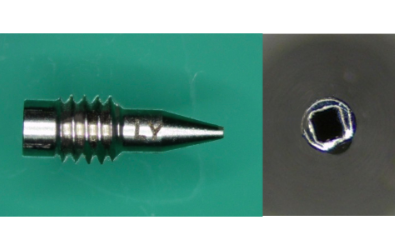

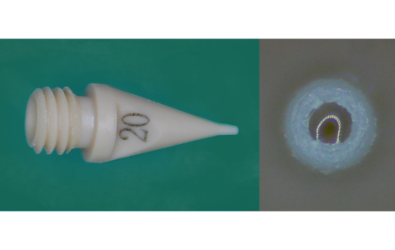

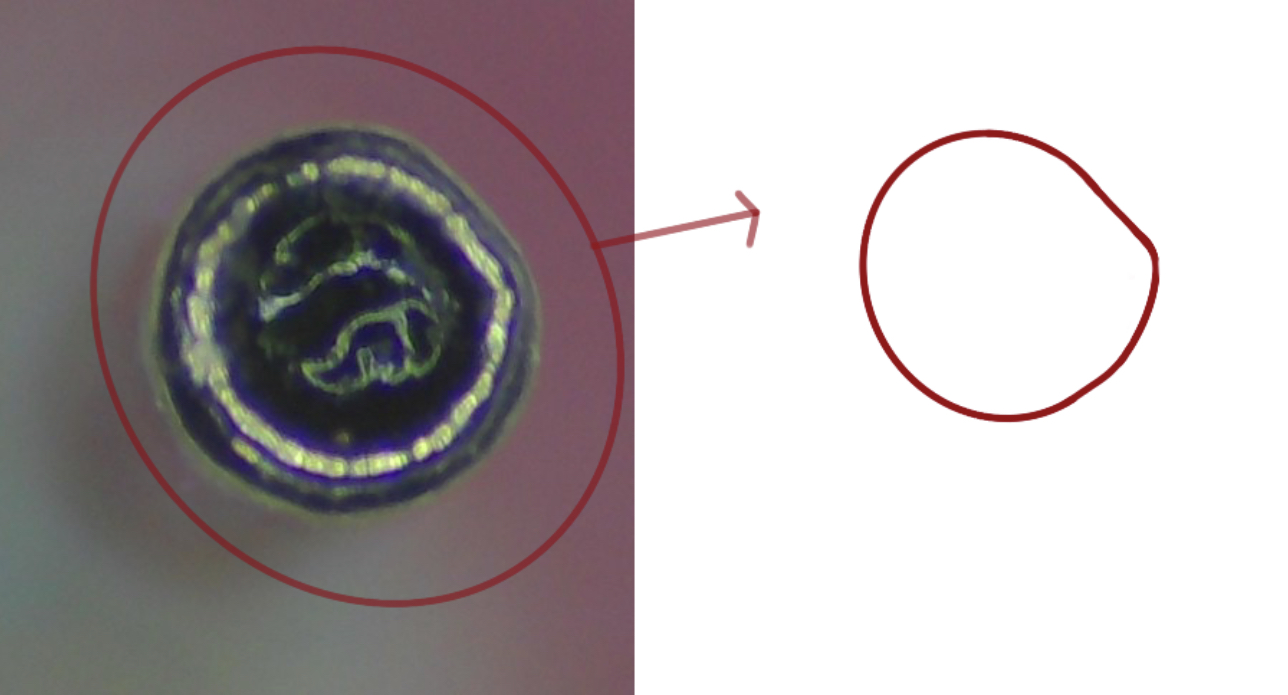

The shape of the hole can be round, square, flat or multi-hole using CIM mold, and the hole tolerance can reach +/-0.02.

Usually individual round holes can use "Wire grinding" to improve the accuracy of the hole, with a concentricity of 0.005mm.

The alumina holes are 0.022~0.60mm, and the tolerance is +/-0.002mm.

The zirconia holes are 0.080~0.60mm, and the tolerance is +/-0.003mm.

Ceramic specifications

Nozzle specification

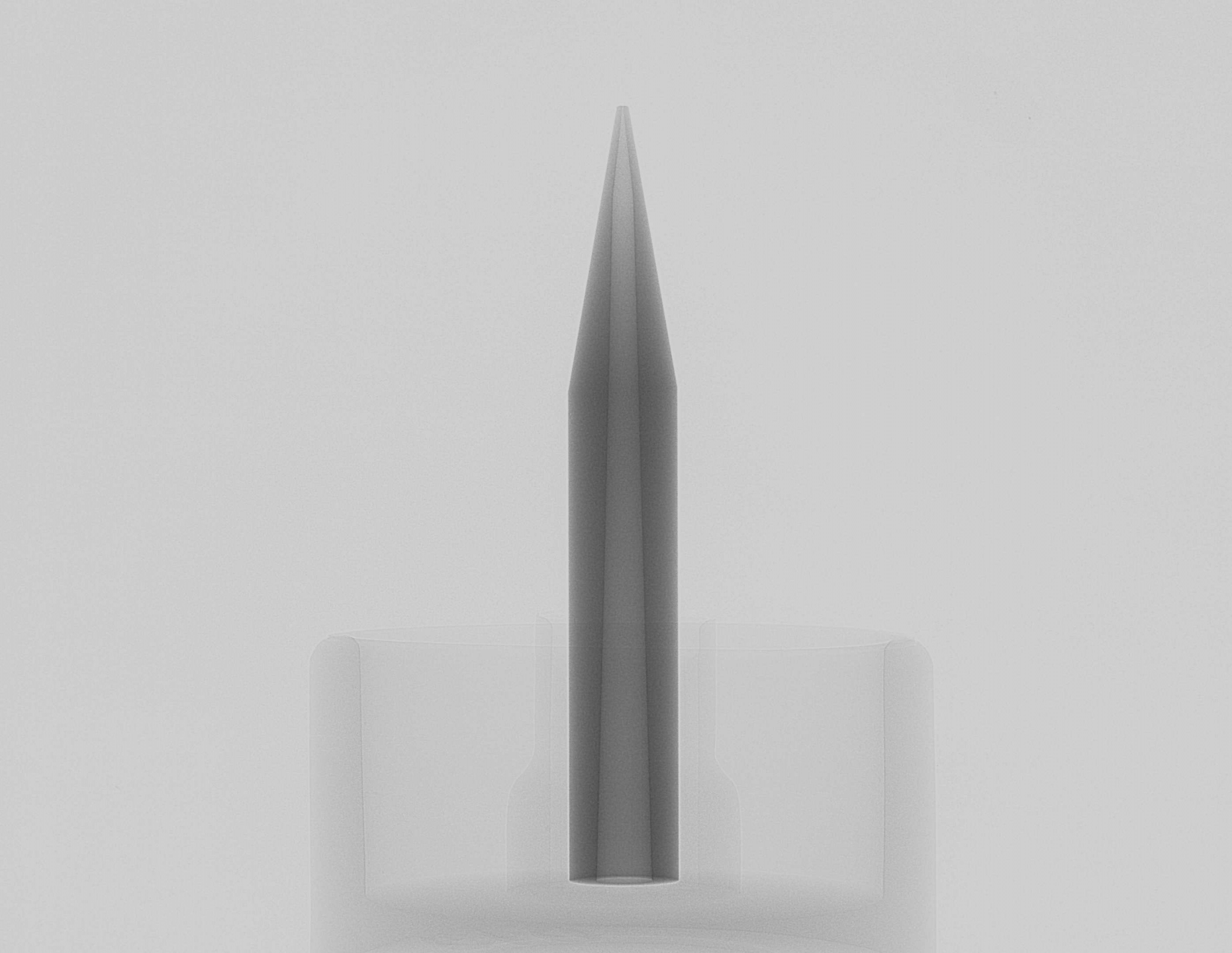

Marked B outer diameter can be designed and grinded according to application requirements, and can be divided into cone type, tube type, needle cone type, cone type + V groove, cone type + tapered hole...

Marked A inside diameter can be designed and grinded according to application requirements. Various ceramics A diemension can be customized according to the required size and up to 0.2mm or more.

Hole Shape and Measurement

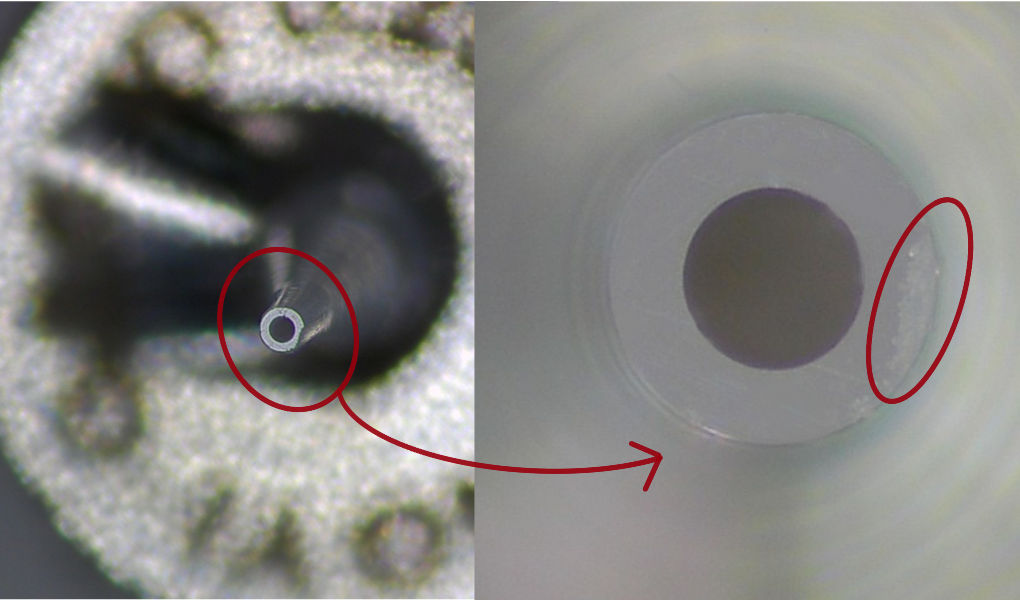

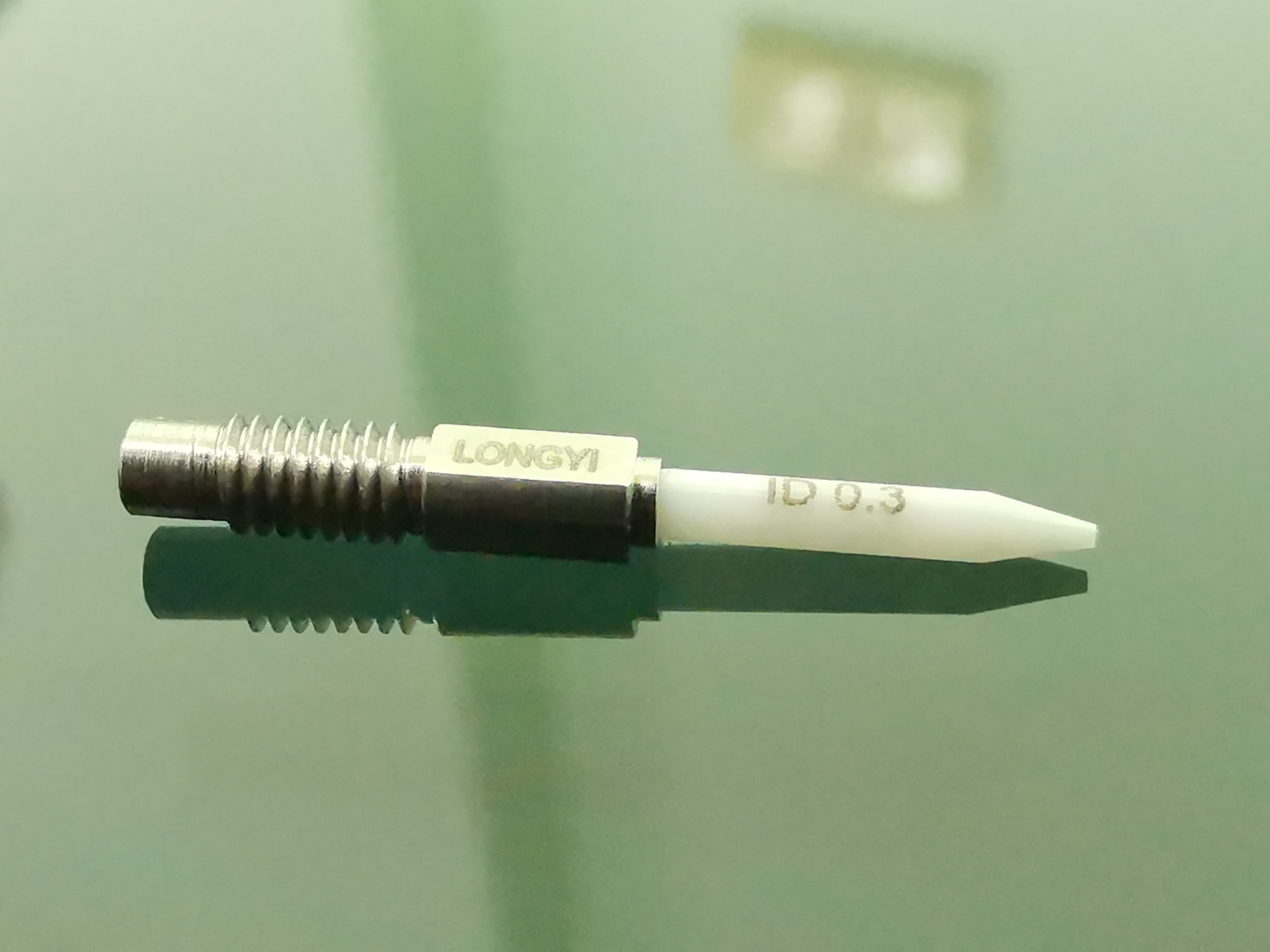

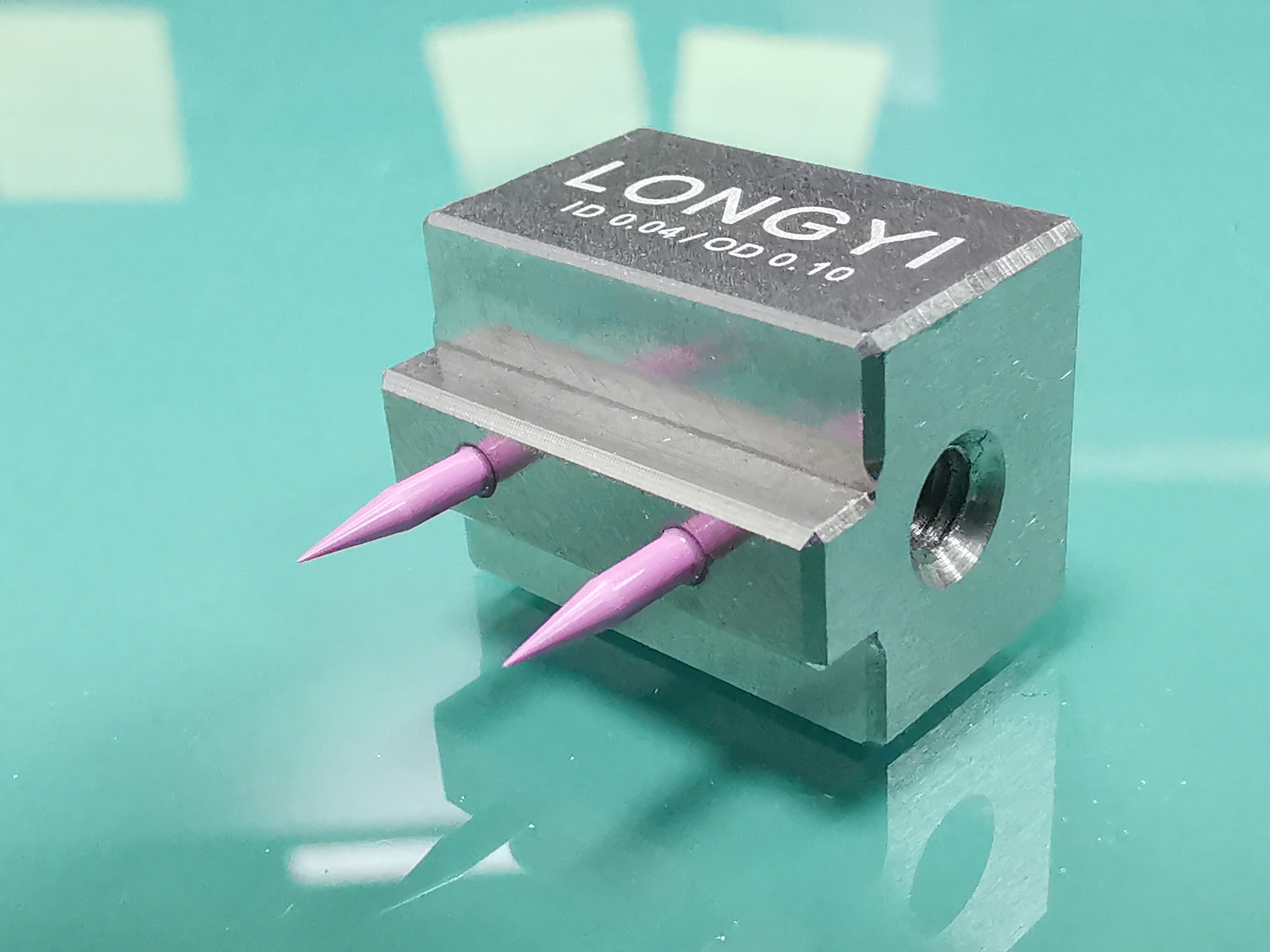

Combination ceramic nozzle

The connectors can be designed and processed according to customer needs, and the materials are mainly stainless steel, PEEK or ceramics. (More)

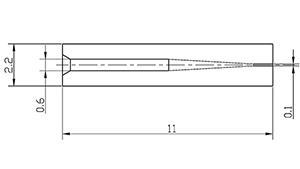

Detail of capillary :

Materials: SUS, Zirconia

NOZZLE TIP DETAILS

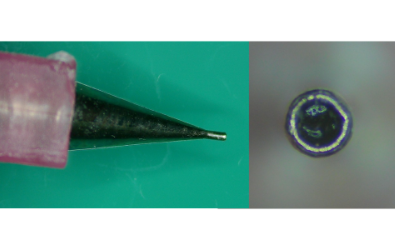

With the ceramic material we can polish the tip and tolerance ± 0.005mm

Ceramic Nozzle Tip 1 - LONGYI

EPOXY DISPENSING NOZZLE - GF2 TIP - LONGYI

METAL NOZZLE - LONGYI

METAL NOZZLE 2 - OTHER

PLASTIC NOZZLE

Advantage of Using Ceramic Tip

Even if it's bump into something and become chipped the inner diameter shape won't change unlike the metal nozzle tip

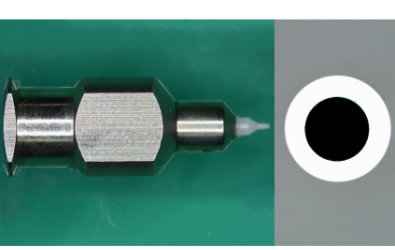

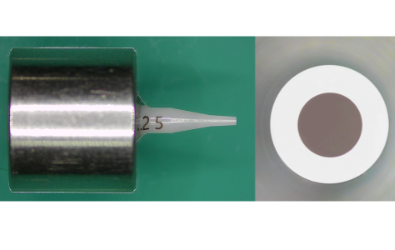

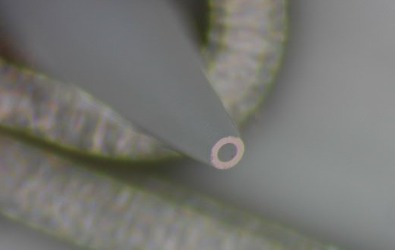

Dispensing micro nozzle VS Small diameter

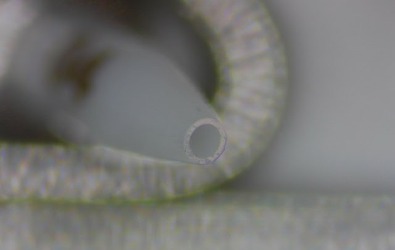

This is our ceramic dispensing nozzle’s tip diameter. You can see these two photos below, one is 0.2mm and the other is 0.3mm.At present, the smallest inner diameter 0.0037mm has been developed

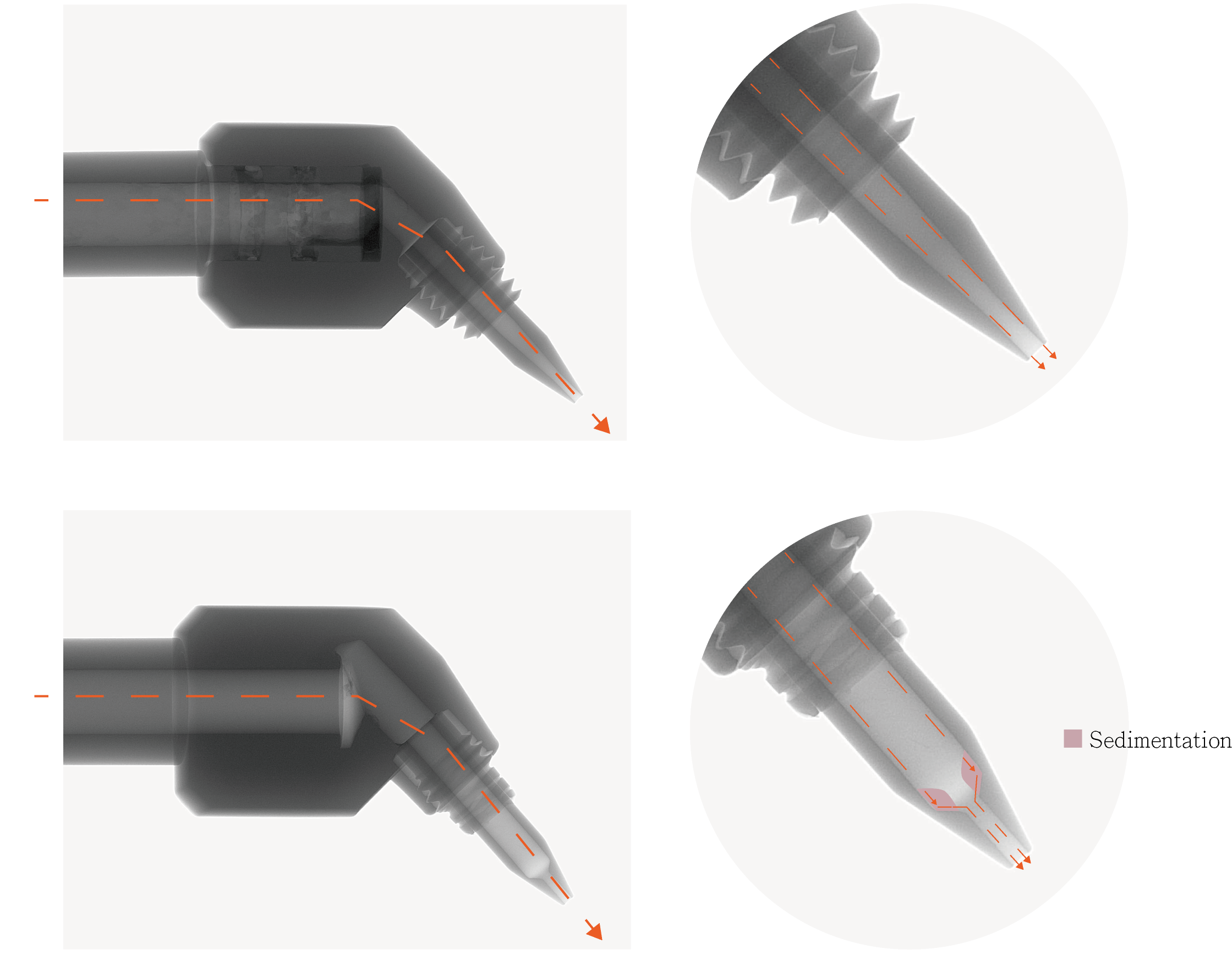

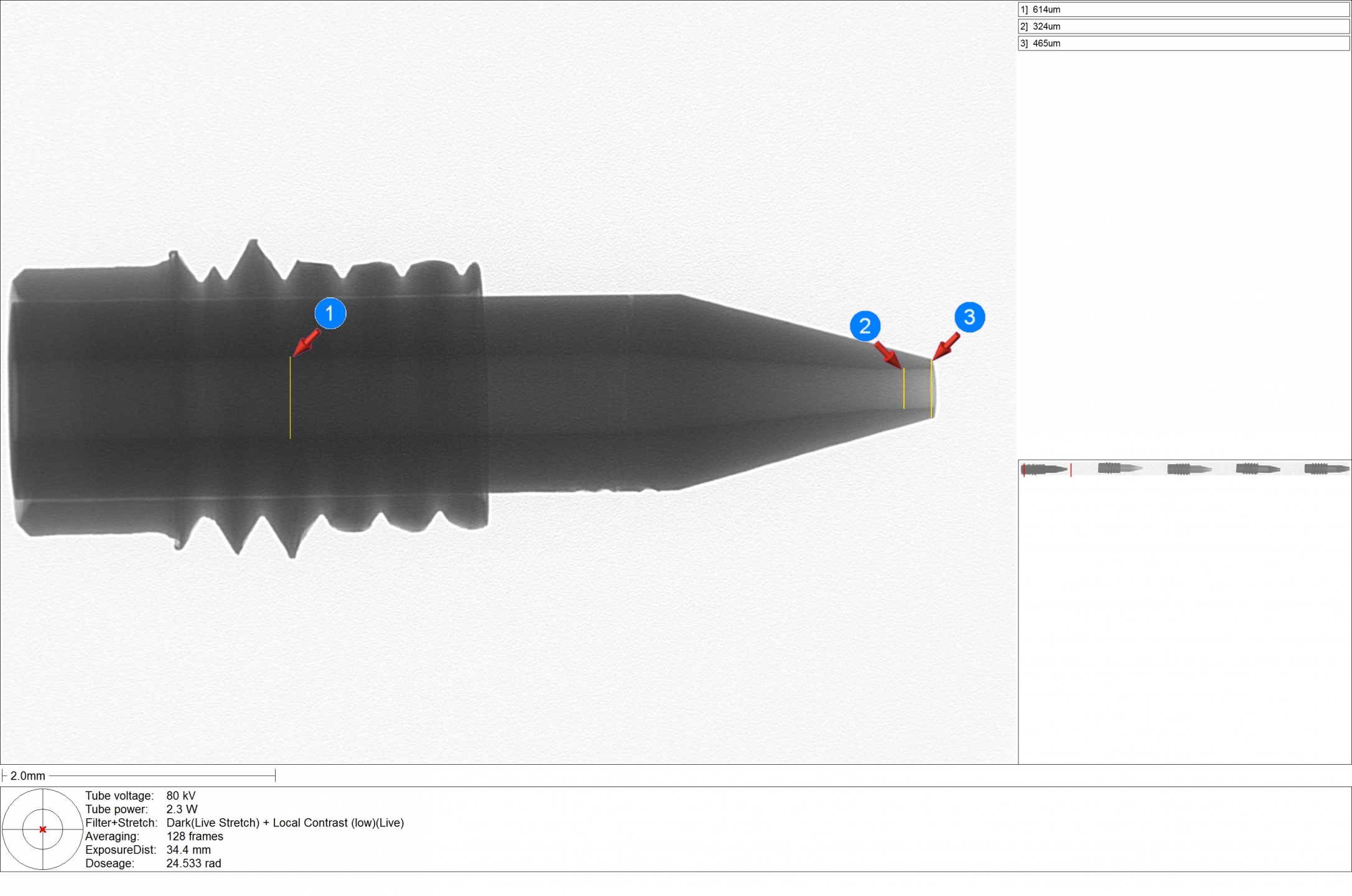

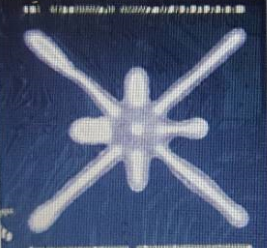

X-Ray Precision Measurement for Ceramic Dispensing Nozzle

LONGYI can provide X-ray and measurement services later and without destroying the sample.

Tungsten steel nozzle VS LONGYI ceramic capillary

LONGY’s capillay is wire-polished and has a very precise inner diameter

with a tolerance of less than 0.003mm.

Ceramic Dispensing glued at 90% speed.

Tungsten Steel glued at 50% or lower speed.

Tungsten Steel glued at 90% speed.

LONGYI develops and fabricates the ceramic and SUS dispensing nozzle different from the common metallic

product. ‧ Adhesive dispensing series ‧ Pick and place series

Material: Zirconia, SUS304

Industry: Semiconductor

Application: Flip Chip / Die Attach / Die Bonding

19L CERAMIC DISPENSING NOZZLE

‧ Adhesive coating ‧ No stuck and leak or too dry

‧ No overspray, no oil mist, and no splash ‧ Can adjust nozzle's atomization pressure

Material: Zirconia, SUS304

Industry: Semiconductor

Application : Flip Chip / Die Attach / Die Bonding

Various products

LONGYI can insert the ceramic capillary into various types of stainless steel.

And can make various specifications according to the inner diameter.

High-magnification microscope measurement (More)

In order to determine the dimensional accuracy and concentricity of the inner diameter,

LONGYI has continuously improved the measuring equipment, and the inner diameter

can be accurately measured at 0.0022mm.

- About usLONGYI

- Products

- Advanced Ceramic & Fine Ceramic

- Hard and brittle materials processing

- Contact Us

- News

- Antistatic-ceramic suction cups officially enter the KLA supply system

- Chinese New Year Celebration Announcement

- Since the epidemic of COVID-19 is serious, the production staffs work separately by turns. Delivery time must be affected by process extension.

- Porous Ceramic Vacuum Chuck + Granite Base

- Company relocation notice

- Ceramic characteristics

- Ceramics Gas Tube ASSY

- Die bonder Dispensing Pin 45mil D/B

- Fittings

- Ceramic Ferrule

- Tokyo Weld / Tester / Packaging Machine / Ceramic Index table

- Ceramic Nozzle

- Ceramic Nozzle

- Ceramic Nozzle

- Die bonder Dispensing Pin D/B

- Porous ceramic vacuum chuck

- Advanced Ceramic & Fine Ceramic

|

LONGYI PRECISION TECHNOLOGY CO., LTD.

Address : No. 705, Longxing Road, Chungli District , 32091, Taoyuan, Taiwan

Tel : +886-3-466-6611 Fax : +886-3-466-7722 |